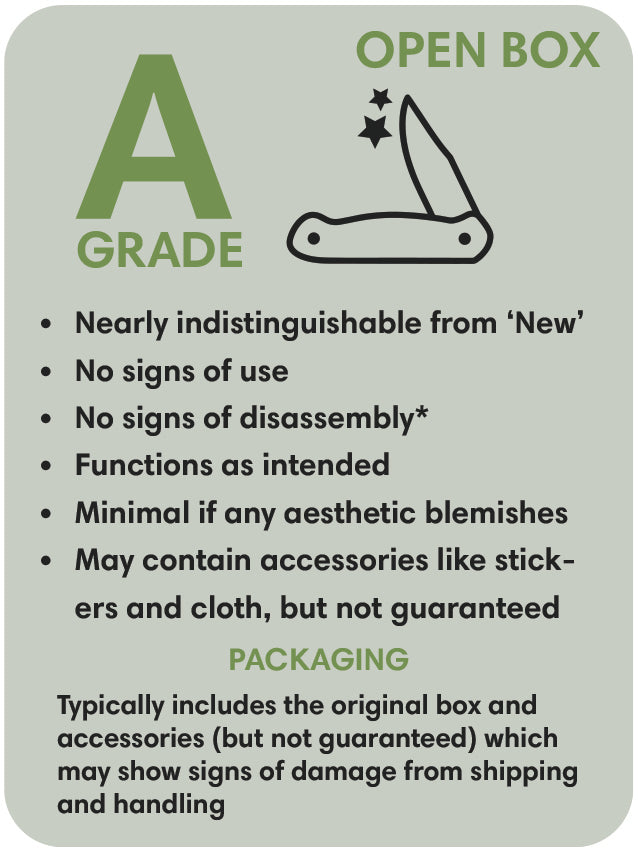

*Knives in Grade A/B have been inspected and all hardware and assembly components show no signs of stripped hardware or other tool marks. We’re confident these knives have not been disassembled, but we are also humans. If something isn’t right with your open-box purchase, drop us a message and we’ll take care of you as always.

**Open box knives may be missing accessories such as tools, cloths, sheaths, etc.

A BEEFY, EXOTIC FLIPPER: The Raine marks multiple firsts for us here at Kaviso. For one, it’s our first collaboration with celebrated knifemaker Kirby Lambert. For another, it’s our first folder with a recurve blade—which are known for their utility for pull cuts and slicing. Measuring 8.2 inches long and weighing nearly 6 ounces, the Raine is a flat-out beast. And while it’s certainly sized for heavy-duty cuts, it doesn’t sacrifice even a smidge of grace. In addition to a thick S35VN blade, the Raine features handle scales made from FatCarbon: a heat-treated carbon fiber composite from a small production shop in Eastern Europe. Hold the knife at different angles and watch the handle shimmer, especially in the light.

EASY TO FLIP & ADMIRE: A good knife is only as good as its handle. That’s why we started with a reliable 6AL4V titanium frame on the Raine, which can be found in all of Lambert’s custom folding knives. Thanks to the caged bearing system (and the 3.5-inch blade’s hefty build), the knife snaps open with authority with a simple press on the flipper tab. To make the flipper even more comfortable, the bolster is rounded and cornered—a design element that can only be achieved through CNC machining. Looking at the Raine from the spine, you’ll notice a floating backspacer that perfectly matches the contours of the handle. To complete the knife, it’s fitted with a titanium clip.

A CLOSER LOOK AT S35VN STEEL: Developed by Crucible Industries (one of the leading manufacturers of specialty steels for the cutlery industry) and Chris Reeve (arguably the most famous knifemaker in the world), S35VN is perhaps the most balanced blade steel ever created in terms of all-around performance. It’s made through a process of powdered metallurgy known as CPM, which results in near perfect consistency in the distribution of carbides. Compared to conventional melting practices, the CPM process produces a steel characterized by superior dimensional stability, grindability, and toughness.

ABOUT KIRBY LAMBERT: Kirby Lambert has been collecting folding knives since the age of 7. Considering his upbringing in the Canadian countryside, he had plenty of reasons to carry one—however, it wasn’t until studying fine art at the University of Calgary that Lambert realized his knack for craftsmanship. Later he met knifemaker Brian Lyttle, who taught him the skills and dedication needed to make his own knives and turn passion into reality. In the 27 years since he officially stepped onto the scene, Lambert has become one of the most respected knifemakers in the industry. To that end, he won the award for “Best Tactical Folder” at Blade Show 2016 and served as the Vice President of the Canadian Knifemakers’ Guild.