More spacious, more stormworthy, more user friendly – just as light.

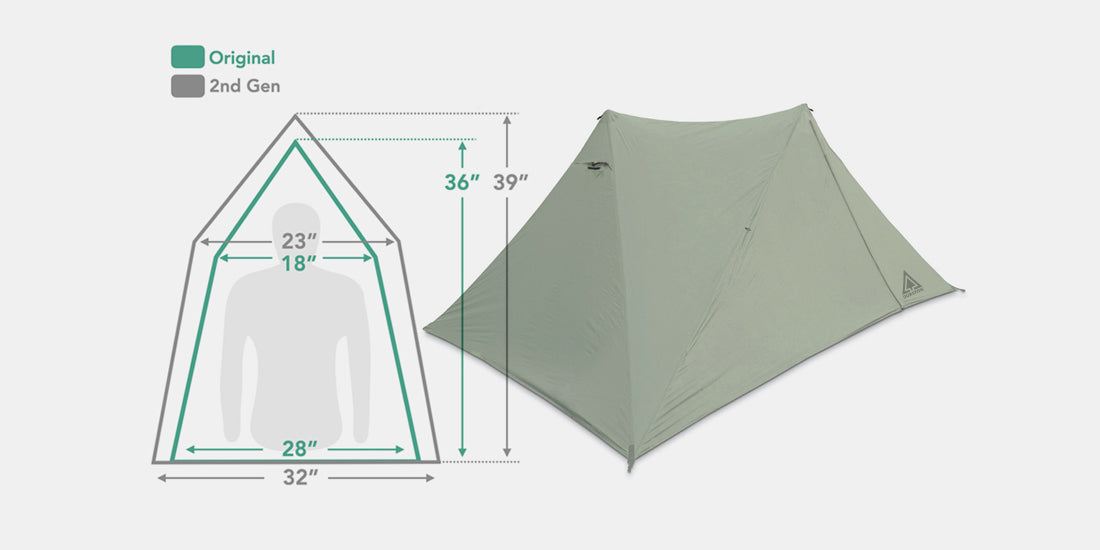

The inner tent is now:

- Longer by four inches (10 cm) to 90″ to fit taller hikers (now recommended to 6’4″).

- Taller by three inches (8 cm) for more headroom.

- Wider by five inches (13 cm) at the shoulders (due to new shoulder height pull outs).

- Wider by four inches (10 cm) at the floor.

For the second generation we’ve addressed this and improved overall stormworthyness by:

- Adding side panel guyouts. These optional guylines support the side panels during high winds to reduce wind deflection.

- Refined the bias/orientation of the fabric to reduce stretch along the corner seams. This reduction in stretch makes the tent more solid in high winds and under heavy snow loads.

- Added catenary cuts along all seams and around the bottom edge of the fly. This allows the tent to pitch tighter on the sidewalls, which also makes it more solid in high winds.

We’ve made further improvements here for the second generation, including:

- New connection points between the floor and trekking pole handles anchor the floor, so it lays more taut. These also allow the inner zippers to operate one handed in both directions.

- New vent design is easier to open/close, eliminates the need for a strap across the opening, and has an “anchor point” to hold the strut horizontally when not in use which makes the tent easier to roll up.

- Doorways on the fly and inner are now 5″ taller for easier ingress/egress.

- Contrasting (black) colors for the door toggles and other accents (e.g. guylines) make them easier to spot in the day, yet still reflective at night. Similarly, the floor is now a charcoal color to make it easier to identify when unpacking the tent.

- Inner ridgeline pockets are updated to be the same style as the X-Mid 2P, which is a more refined design and avoids sagging under the weight of heavier items.

With the second generation X-Mid 1P we’ve saved weight by:

- Eliminating unnecessary seams in the inner tent by moving the door zippers flush to the edge of the bathtub floor and directly below the peaks.

- We’ve used a waterproof seam construction (double needle lap felled seam with waterproof thread) on the two fly corner seams that are above the vestibules, which is lighter than seam tape. We now use this construction throughout the fly, but we are still seam taping the crucial seams above the inner tent out of caution.

- New inner pocket design saves a few grams of mesh.

- New simpler vent design saves weight with less velcro and webbing.